Hello everyone! My name is Braxton Cody, and next year I will be in my third year at Northwestern University studying Mechanical Engineering. This summer I have been working with Jonathan Emery of the Material Science Department at Northwestern University and Charudatta Phatak of the Material Science Division at Argonne National Laboratory to figure out how to create cylindrical nanotubes of Cobalt metal to characterize and the magnetic domain walls based on the curvature of the metal. To guarantee even coatings of Cobalt metal, atomic layer deposition (ALD) techniques will be used as a means to gain extremely precise control the thickness of the metal on the order of angstroms.

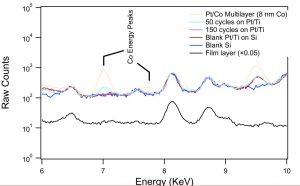

During the first part of this summer, I collected data regarding a specific ALD process for Cobalt recently developed by the Winter Group of Wayne State University. After establishing the specific processing parameters, becoming familiar with the various characterization techniques, and ordering the chemicals required for the ALD process, we began implanting the process resulting in varying degrees of success. We did manage to grow Cobalt metal as seen in the x-ray fluorescence data shown below. The data for the Pt/Co multilayer (shown in beige) was created using sputtering deposition as a standard for comparison, providing information about the measurement sensitivity and accuracy.

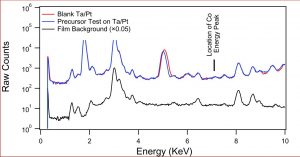

Despite growing Cobalt metal, we soon discovered that a preparation error resulted in exposing the chemical to air ruining the precursor chemical. We ran a test to confirm our suspicions, and in the x-ray fluorescence data, there is no energy characteristic peak corresponding to Cobalt atoms, as seen in the figure below. Due to the expense of the chemical, we’ve begun pursuing alternate Co metal growth methods using plasma-enhanced ALD

Although we have encountered numerous setbacks, we will continue working towards controlled ALD of Cobalt. We are now researching new options involving Plasma-enhanced ALD as a cheaper and potentially more effective option. Due to the timeframe of this project, we hope to test this new chemistry on flat substrates and confirm Co metal deposition before the end of the summer. If that endeavor proves successful, we will proceed to grow the nanotubes and characterize their magnetic structures. While the previous weeks’ results have not proven successful, they have provided us with new directions for this project and set the groundwork that is instrumental in the continuation of this project.