Hello, my name is Patricia Lohman and I am a rising sophmore studying material science and engineering at Northwestern University. I work under Meltem Urgun-Demirtas and Patty Campbell on in a bioprocess and reactive separations group. This summer I was tasked with bioprocessing for additive manufacturing or making 3D printable pastes made of food waste.

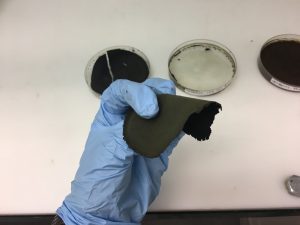

For much of the summer performed literature searches to compile a list of procedures for making biofilms out of different food waste. This included food waste with three different types of base materials. Vegetable and fruit waste (peels, shells, and seeds) made of cellulose, egg shells made of calcium carbonate, and shrimp shells from which chitosan could be extracted from. After the search, I worked in lab recreating the biopolymers found in the studies. I started with fruit and vegetable waste materials. To do so the process involved digesting dried plant waste material in dilute acid and casting the resulting mixture. In particular, spinach waste produced a flexible film.

Figure 1: Spinach waste biofilm

The egg shell biomaterials began with dried and fine egg shell powder and was mixed with a binder solution until a clay-like paste was produced. The clay could be molded easily and held its shape.

Figure 2: Egg shell paste

The above egg shell paste used less than 90 µm egg shell powder and sucrose water in a 1:1 ratio as a binder.

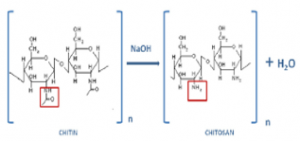

Shrimp shells do not have chitosan directly available. The shells once demineralized and deproteinized start with chitin. Chitin then undergoes a deacetylation reaction with concentrated NaOH at high temperatures to remove the acetyl group and convert chitin into chitosan.

Figure 3: Chitin to chitosan deacetylation

The effectiveness of the reaction is key in determining the crystallinity, hydrophilicity, degradation, and mechanical properties of chitosan biomaterials. The target was to produce chitosan with a degree of deacetylation of 60% or greater. In lab I began working with pure purchased chitin and performing the deacetylation process under different conditions and measuring the degree of deacetylation. I plan to work on changing the concentration of NaOH, temperature, and conducting the reaction in an inert atmosphere to achieve that degree of deacetylation. After isolation, chitosan can be added to a number of organic solvents to form an extrudable paste.

Once the biopolymers were replicated, I planned on manipulating process parameters to achieve a consistency of paste that could be extruded by the Discov3ry extruder attachment, made especially for pastes, with an Ultimaker 3D printer.

Making bioplastics out of waste material is not only a novel idea, its an essential one. Food and plastic waste are glaring problems that have vast detrimental consequences on the planet. Finding alternatives to the materials used everyday is a good first step to tackling the issue. This project does a great job of addressing waste issues and providing exciting advances for additive manufacturing. I am very grateful that I was able to work on an impactful project and am excited to see where it goes. A special thank you to my PI’s and Dr. Jennifer Dunn for all their help this summer.